Our brochure as a PDF file for download - please register

Lines for the production of air-cooled blown films

HDPE Films

Line layout

- number of layers: 1 or 3

- raw materials: HDPE pure or with blends (also biopolymers)

- film thickness: 6 μ – 80 μ

- film width: 1.000 mm – 3.000 mm double layflat

- output: up to 600 kg/h

- line speed: up to 300 m/min

Film characteristics

- superior thickness tolerances

- outstanding flatness

- excellent mechanical properties

- temperature resistant

- tear resistant

- grease proof

- fully recyclable

B l o w i n g t h e s h a p e

Applications

Added values

- over 40 years of know-how in HDPE blown film lines

- state-of-the-art machine concept installed at leading HDPE film manufacturers

- reliable and flexible machine layout

- reliable production of 6 μ thin film in continuous operation

- continuous production rate of up to 300 m/min

- optimal synergy between extruder screw, die, cooling ring and winder

- high degree of PCR can be processed (up to 100%)

- common bio polymers can be processed

- high degree of line automation on demand

Application areas

- bags / sacks / hoods

- paper match film

- coating and laminating film for food or non-food applications

- liners

- covering film

- flow pack films

- labels / sleeves

- wrapper film / sheets

Polyolefine Non-Barrier Films

Line layout

- number of layers: 3 / 5

- raw materials: PE, PP, EVA, biopolymers, blends, and others

- film thickness: 10 μ – 250 μ

- film width: 1.000 mm – 3.000 mm double layflat

- output: up to 1.000 kg/h

- line speed: up to 200 m/min

Film characteristics

- superior thickness tolerances

- outstanding flatness

- excellent mechanical properties (e.g. strength and balanced shrink)

- adjustable film surface (e.g. sticky, smooth, glossy)

B l o w i n g t h e s h a p e

Applications

Added values

- reliable and flexible machine layout

- wide range of film thicknesses

- wide range of blow-up ratios

- long neck / short neck production mode

- high degree of line automation on demand

- turnkey solutions for many applications

Application areas

- bags and sacks

- industrial and transportation packaging (e.g. HDSS)

- agricultural films

- lamination film

- shrink and stretch hoods

- paper match film

- liners

- flow pack films / frozen food packaging

- protection film

- collation shrink films

Barrier Films

Line layout

- number of layers: 7 / 9 / 11 / 13

- raw materials: PE, PP, PS, PET, PA, EVOH, EVA, Ionomer, biopolymers and others

- film thickness: 20 μ – 250 μ

- film width: 1.000 mm – 3.000 mm double layflat

- output: up to 800 kg/h

- line speed: up to 200 m/min

Film characteristics

- superior thickness tolerances

- outstanding flatness

- wide range of raw material selection

- medium to highest barrier properties

- sealing properties (e.g. easy peel, re-closable seals)

- adjustable anti-fog properties

B l o w i n g t h e s h a p e

Applications

Added values

- most advanced die head design using the synergies with Triple Bubble® technology

- reliable and flexible machine layout

- wide range of film thicknesses

- outstanding gauge tolerances

- high degree of line automation on demand

- turnkey solutions for many applications

Application areas

- vacuum skin packaging (VSP) films

- vacuum packaging films

- thermoforming films

- high barrier lamination films

- lidding films (easy peel, seal films)

- specialty films

Kuhne Anlagenbau GmbH

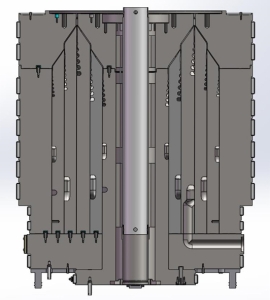

Kuhne Anlagenbau designs and manufactures blown film dies optimized for every application. For top quality and reliable supply, the dies are manufactured in-house in a state-of-the-art facility that guarantees the tightest design tolerances.

ReCon

HyCon®

MoCon®

Smart Bubble® HDPE

For mono and three-layer dies, we use our ReCon (regular concept) spiral mandrel die, which is well proven and ideal for high pressures, as in HPDE film production. This design, in conjunction with our precise manufacturing technology, delivers tight thickness tolerances for very thin films.

Smart Bubble® non barrier films

Standard three and five-layer systems are usually also equipped with ReCon (regular concept) spiral mandrel dies unless the customer is considering a later expansion for additional layers. In this case, a MoCon® (modular concept) stackable plate die is recommended. This Kuhne concept offers maximum flexibility combined with a solid system design.

Smart Bubble® barrier films

For 7- to 13-layer systems, our customers benefit from synergies, developed over many years, between our conventional blown film technology and the highly sophisticated systems of our Triple Bubble® technology.Seven and nine-layer systems are often equipped with HyCon® (hybrid concept) dies, consisting of a core of spiral mandrels with the outer layers applied via stackable plates positioned just before the die exit.

These layers can be heated independently of the temperatures of the rest of the blown film die, which is a very important feature for PA or PET outer layers.

The MoCon® (modular concept) stackable plate die is ideal for film structures with up to 13 layers (17 layers are possible) since this design will provide a shorter flow path and an optimal residence time. This concept offers maximum flexibility so that new market requirements, such as films designed for recyclability, can be fulfilled quickly and without additional costs.

KUHNE Anlagenbau GmbH – we are member of the Kuhne Group

Blown Film, Flat Film & Sheet Extrusion

KUHNE Group is one of the leading European machine builders for film and sheet production.

Contact

News

Turnkey systems for sustainable food packaging25. April 2024 - 12:33

Turnkey systems for sustainable food packaging25. April 2024 - 12:33 SUPERIOR WATER QUENCHED BLOWN FILM LINES FOR MEDICAL FLUID BAGS8. October 2022 - 18:32

SUPERIOR WATER QUENCHED BLOWN FILM LINES FOR MEDICAL FLUID BAGS8. October 2022 - 18:32