Cool Bubble®

- Medical film

- Food films

- Technical films

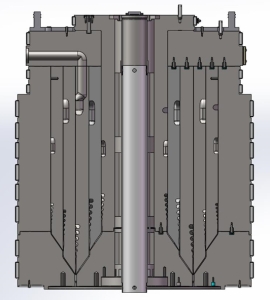

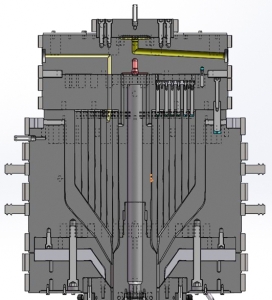

- Die-Head Concept

Cool Bubble®

Our brochure as a PDF file for download - please register

Kuhne Anlagenbau designs and manufactures blown film dies optimized for every application. For top quality and reliable supply, the dies are manufactured in-house in a state-of-the-art facility that guarantees the tightest design tolerances.

Cool Bubble® medical films

Medical films are typically 3, 5 or 7-layer structures, depending on the application. Some of them require thermally sensitive polymers like PVC/PVDC, EVA or EVOH used in combination with polyolefins as the bulk material. It is important to optimize the die design for the structures to be produced.

Our ReCon (regular concept) spiral mandrel design is the proven solution for 3 and 5-layer structures. For more complex 7-layer structures, our MoCon® (modular concept) stackable plate die is ideal since it provides much more flexibility in film structure design.

Additionally, our MoCon® die can be configured with thermal isolation to be able to process very heat sensitive resins like PVDC. Both options, in conjunction with our precise manufacturing technology, delivers tight thickness tolerances for very thin layers.

Cool Bubble® food packaging films

Water quenched blown films used in food packaging are generally bottom forming webs of 9, 11 or 13 layers. These consist of several layers of PA coextruded with PE layers and an EVOH layer for barrier. Due to the most aggressive quenching in the market, Cool Bubble® lines designed for this application deliver very high output, which requires high processing pressure. Our MoCon® (modular concept) stackable plate die can operate with pressures up to 1000 bar and delivers the best combination of high output and excellent thickness control.

Cool Bubble® industrial films

Choosing the right die design for a particular application depends on the film structure and properties of the polymers to be used. Our three die concepts offer all possible options for the best processing solution: (1) the ReCon (regular concept) spiral mandrel die, (2) the HyCon® (hybrid concept) die, a combination of spiral mandrels and stackable plate mandrels, and (3) the MoCon® (modular concept) stackable plate die. In many applications, our Cool Bubble® process, in combination with one of the die concepts above, makes it possible to provide a solution for industrial films or tubing that are difficult, inefficient, or impossible to produce by conventional blown film.

One example is the extrusion of tubing using tacky or sticky resins with low melt strength. Another example is the coextrusion of a high barrier film or tubing with PVDC, a very heat sensitive resin, as the barrier layer. In this case, our MoCon® die can be configured with thermal isolation in the PVDC layer to be able to process it without degradation. If required, this same layer can also be used to process EVOH without any changes. In all cases it is still possible to keep high outputs with great thickness control.

KUHNE Group is one of the leading European machine builders for film and sheet production.